Home Products and application

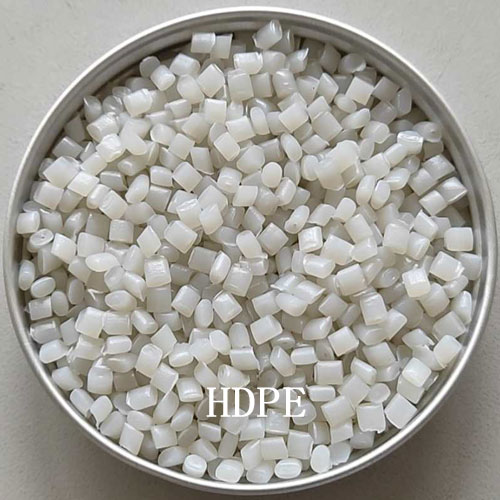

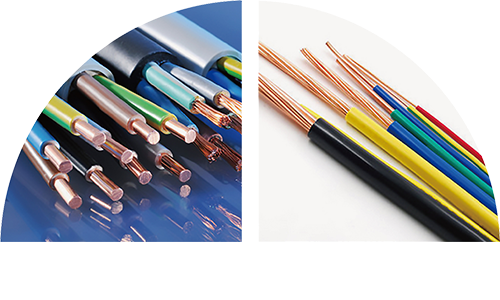

HDPE cable sheath material particles

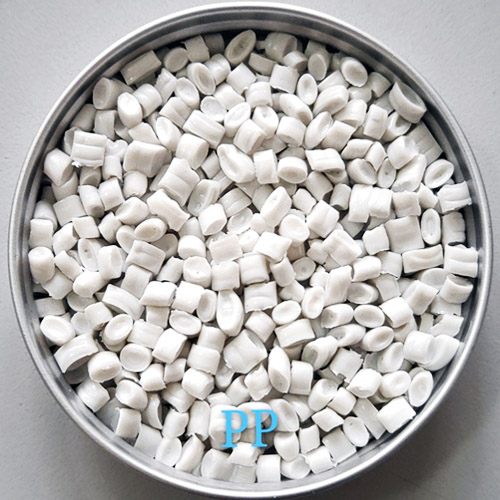

MDPE optical cable sheath material particles

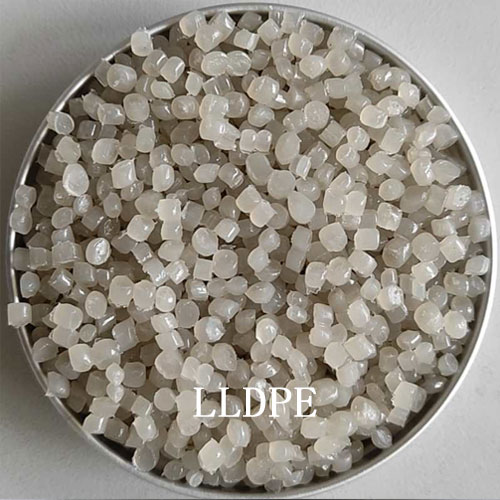

LLDPE optical cable sheath material particles

CopyRight © 2019 Changzhou Jinyong Technology Materials Co., Ltd All Rights Reserved

Mailbox: office@tcjinhui.com Tel: 0519-83131151 Powered BY: Suyee Inc.